March 27, 2013 - Coal Tar Removal Success - Validated

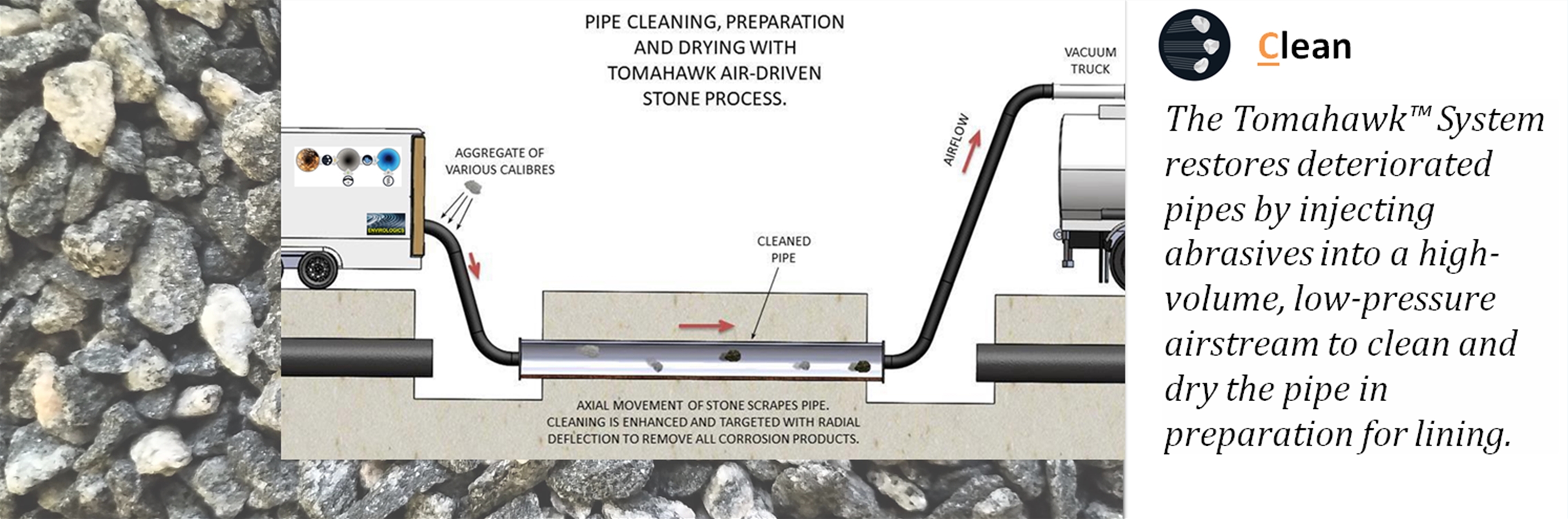

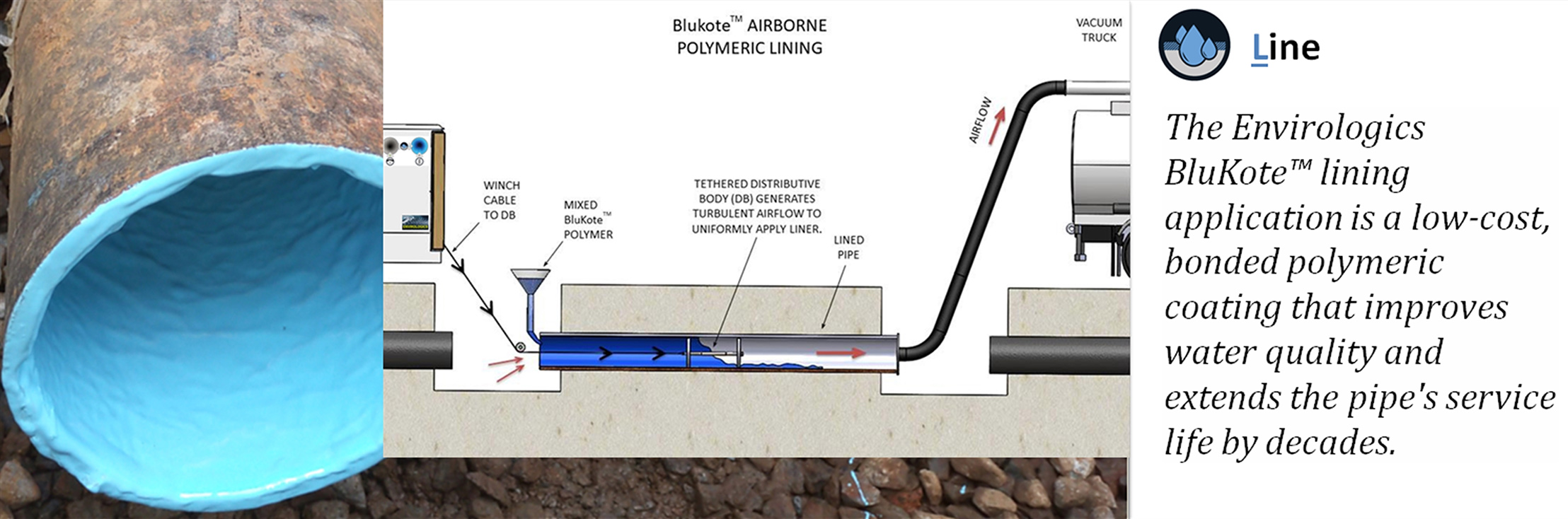

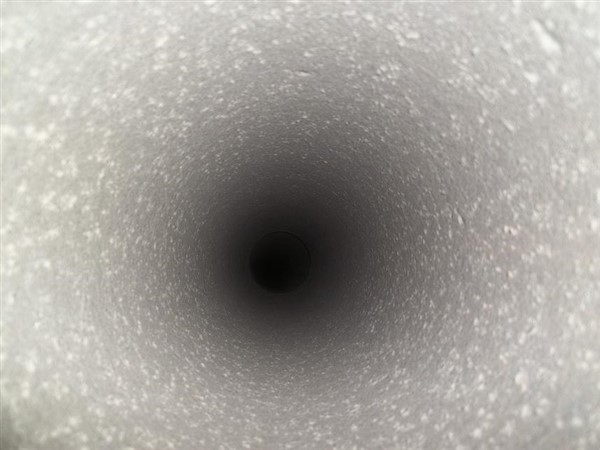

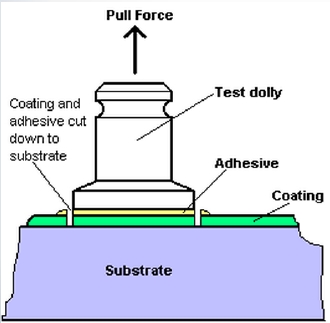

Third party test results have confirmed that the bond between the new liner and host pipe wall exceeds 250 psi. The 6" cast iron water pipe was cleaned of tuberculation and the old coal tar liner then dried using our Tomahawk System™. The pipe was then lined using an SIPP (Spray In Place Pipe) technology. The excellent bond results will ensure a leak free pipe for years to come.

Actual pipe with corrosion products and coal tar lining. At right, same pipe after being cleaned and dried using the Tomahawk System™. Pipe is prepared and ready for lining material.

ASTM D4541 adhesion test.

Contact us at Envirologics for more information on how to remove coal tar from your municipal water pipes.