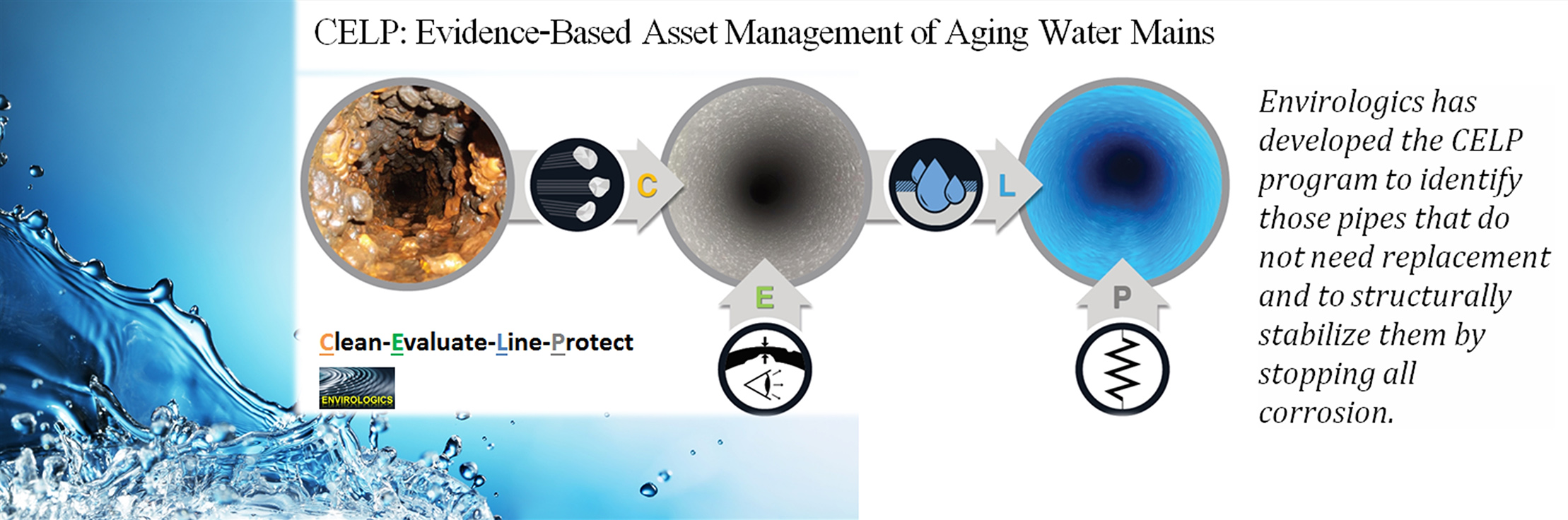

Tomahawk Cleaning

![]() Clean

Clean

Condition of Our Watermains

Tuberculation and Encrustation - Need to clean tuberculation and corrosion deposits out of your drinking water pipes and fire mains prior to lining? The Tomahawk™ System can help you on your pipeline rehabilitation project.

A corroded and tuberculated potable water pipe. At right, the same pipe cleaned and prepared by the Tomahawk™ System. This pipe is now clean, dry and ready for liner application.

Tar and Bitumen Linings - Need to clean old bitumen and tar lining materials out of your drinking water pipes? The Tomahawk™ System can do it with ease. Bitumen and tar linings were used in potable water pipes to prevent corrosion. These materials are still found in pipes throughout North America.

A bitumen tar and tuberculated potable water pipe. At right, the same pipe cleaned and prepared by the Tomahawk™ System. This pipe is now clean, dry and ready for liner application.

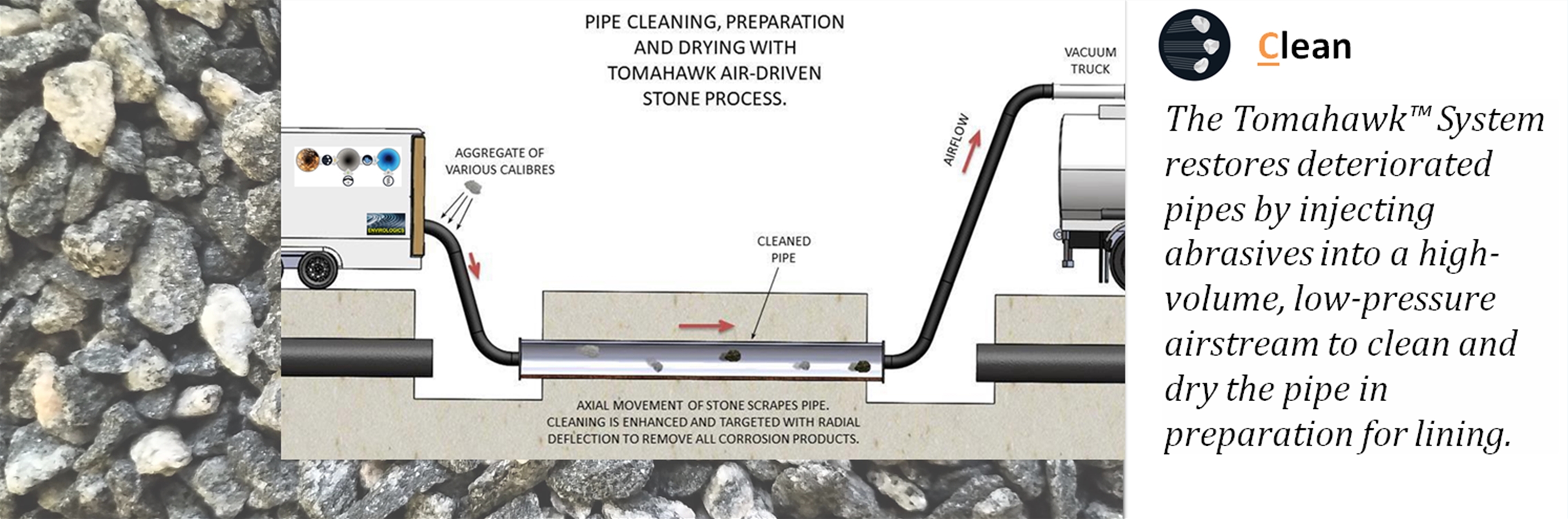

The Tomahawk Solution

The Tomahawk™ System restores deteriorated pipe by injecting abrasives into a high-volume, low-pressure airstream to clean and dry the pipe in preparation for lining, while using little to no water. Tomahawk can clean pipes from 100mm (4") up to 300mm (12") in diameter. For a Tomahawk cleaning overview document which includes stone abrasives, vac tuck, access pit, Scout specifications and more, please click here.

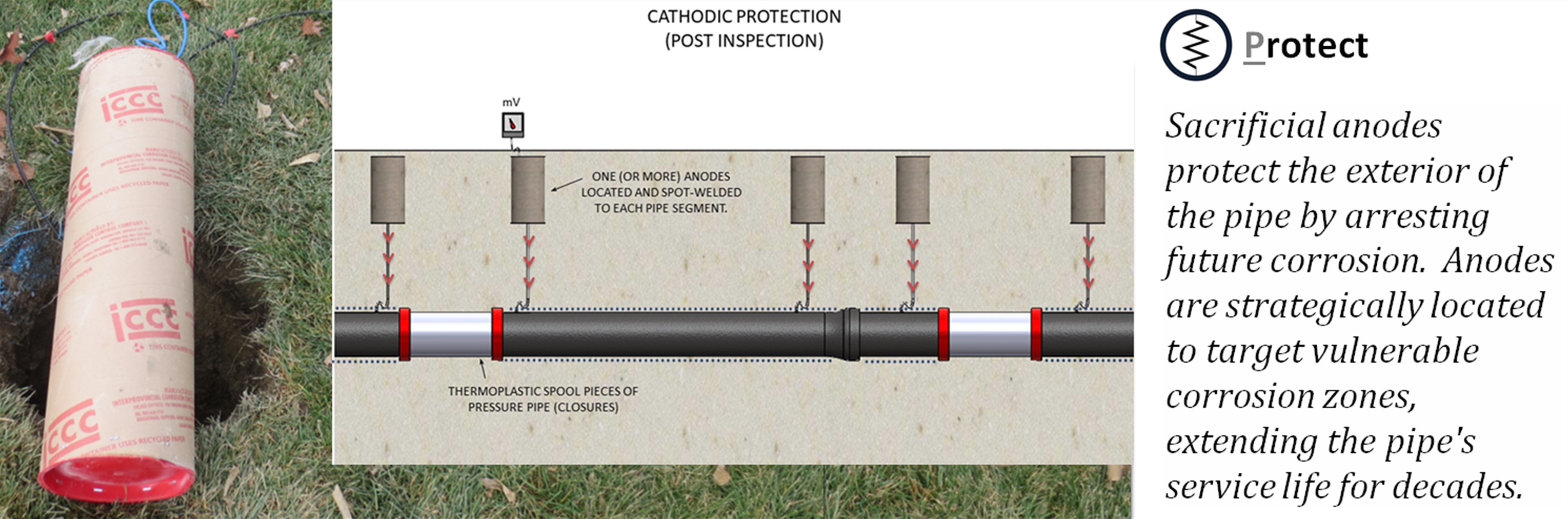

Above, Tomahawk Airborne Abrasive Cleaning System Schematic.

Above, Tomahawk Airborne Abrasive Cleaning System Schematic.

- Improves drinking water quality

- Restores water pressure and flow rates for drinking water and fire fighting

- Lowers operating costs for distribution networks

- Dust-free, environmentally friendly, trenchless process

- Uses little to no water, reducing waste by up to 98%

- Quickly removes tuberculation, biofilms, old bitumen or coal tar linings

- Best-in-class surface preparation for superior bond and long-term, leak-free performance

- Dries the pipe for immediate liner application

- 100mm (4”) to 300mm (12”) diameter pipe

- Clean up to 135m (450 feet)

- Up to 40% tuberculation levels

- One 22.5° elbow per segment

- Meets or exceeds surface preparation and bond requirements for ASTM F3182 for SIPP applications

Tomahawk™ Pipe Cleaning and Preparation Overview

Click on the left picture below for an overview of the Tomahawk pipeline cleaning and preparation process. Click on the right picture below to view a video showing the trenchless street from a unique bird's-eye view, no water bypass installed.

Final Inspection Video

Click on the icon below for a short pipe and service connection inspection video following Tomahawk cleaning. The white cavities seen in the pipe wall are left behind following the removal of loose graphitic corrosion during cleaning. This helps to ensure a strong liner bond to the pipe wall. The pipe and service connection are clean, dry and ready to accept liner material.

Why Dry Pipe Cleaning?

- Municipalities are looking for ways to reduce water consumption, especially in more arid regions.

- Less mess, odours and waste onsite, improving public perception.

- Cost savings due to: less water consumption during rehab activities, pipe is dried quickly in preparation for lining, vac truck can stay onsite cleaning pipe all day long without having to dump debris.

The Importance of Liner Bond

The video below highlights the importance of a strong bond in preventing future leaks. The arrows represent water pressure in a typical water main. Axial forces are a result of moving water. Positive tangential forces are normal. Negative tangential forces can occur when fighting fires or during transient conditions such as when a water hammer event occurs.

Third party test results have confirmed that the bond between the liner and host pipe wall exceeds the 250 psi bond strength required by the ASTM F3182-16 "Standard Practice for the Application of Spray-Applied Polymeric Liners Inside Pipelines for Potable Water". The pipe wall was cleaned and prepared up to a SSPC-SP 6/NACE No. 3 equivalent surface by Tomahawk. The original lining material found in the host pipe was coal tar. This makes the results even more impressive due to its tenacity towards removal.

Rustbusters

For a light-hearted video of the state of our drinking water infrastructure and how the Tomahawk™ System can help, click on the picture below to watch the Rustbusters in action.